| Product Name | Modern School Lab Safety Storage Fire Proof Explosion-Proof Metal Cabinet for Gas Cylinder | ||

| Measurement: | 900*450*1900cm/550*450*1900cm/1200*450*1900cm | ||

| Material: | High quality 1.0mm cold-rolling steel | ||

| Spraying: | Water-washable copper plating, electrostatic powder high-temperature curing spraying | ||

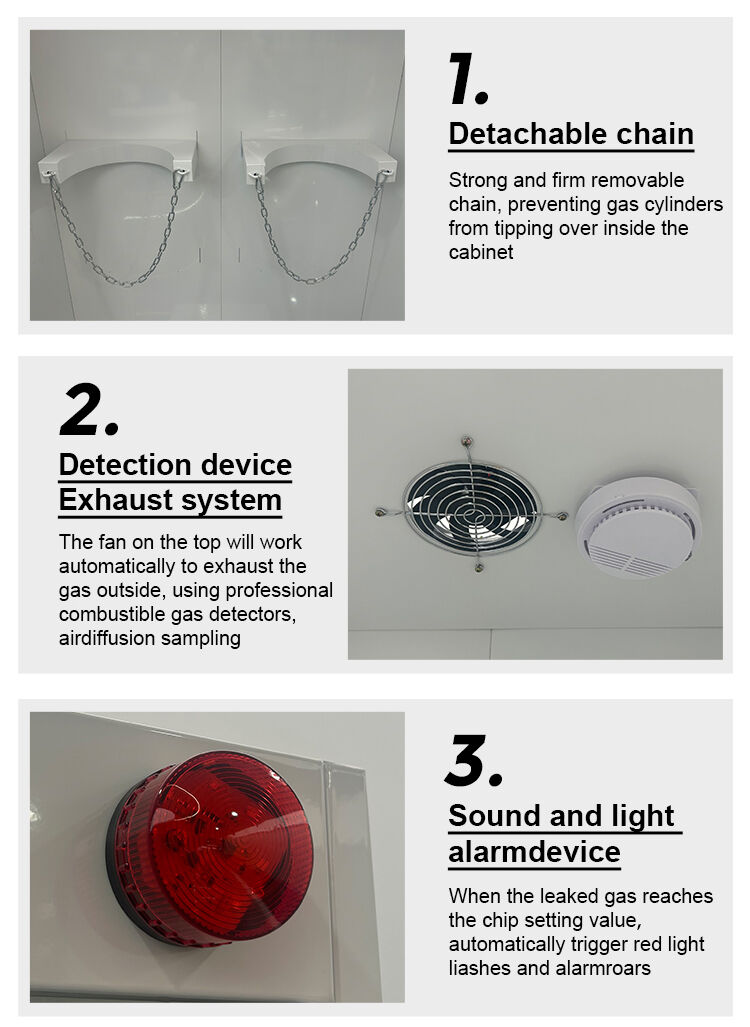

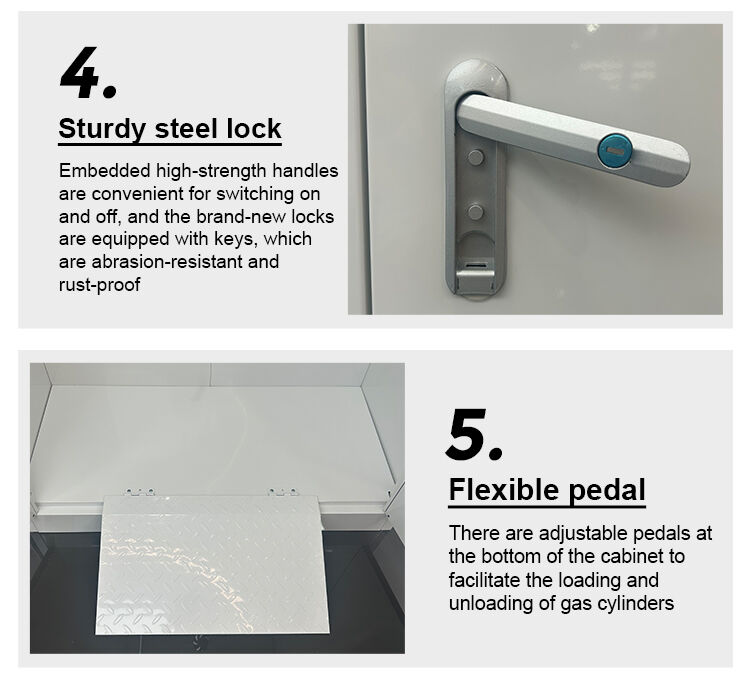

| Structure: | Whole welding/single-layer structure/detachable steel hoop (chain fixed)/door hinge pin / zinc alloy handle lock/Movable flap | ||

| Color: | Overall gray-white wrinkle finish | ||

| Selection Guide: | No Alarm Detection Gas Class :Nitrogen, Oxygen, Helium, Neon, Argon | ||

| First Generation Alarm Detection Gas Class :Methane, Propane, Propylene, Butane | |||

| Second Generation Alarm Detection Gas Class:Methane, Propane, Propylene, Butane, Butylene, Ethyl Alcohol, Acetylene, Hydrogen | |||

| Alarms: | Adopting special combustible gas detector, air diffusion sampling, when reaching the concentration set by chip cut point, it will alarm automatically. With the alarm device, a line connection, in 5 seconds after the alarm automatically start the exhaust device, dilute the combustible gas concentration until below the chip cut point set value. | ||

| general use | Commercial Furniture | material | Cold rolled steel |

| Application | Office Building, Hospital, Workshop | design style | Modern |

| type | Laboratory Furniture | place of origin | Zhejiang, China |

| brand name | Rio Tinto | model number | GC-F1 |

| Product name | Gas Cylinder Cabinet | Measurement | 900*450*1900cm |

| Color | Overall gray-white wrinkle finish | Usage | Chemical Institute |

| Structure | Detachable | Certificate | ISO9001, ISO14001 |

| Warranty | 2 Years | Feature | Movable shelf |

Gas cylinder storage cabinets are used for storage of gas cylinders in laboratory, workshop and etc. Its function is to protect the gas cylinder stored within from exterior fire, and contain the fire within the cabinet from the surroundings if any. Special purpose alarm device and automatic exhaust system can be installed according to the storage requirement, further enhancing safety to the environment.

Primary Purposes & Benefits

1. Containment of Leaks: The most critical function. If a cylinder valve or regulator leaks, the cabinet contains the gas, preventing it from spreading into the workspace.

2. Hazard Segregation: Isolates incompatible gases (e.g., flammables from oxidizers) from each other and from ignition sources.

3. Physical Protection: Protects cylinders from being knocked over, damaged, or tampered with.

4. Fire Protection: Provides a defined fire-resistant barrier (typically 30-minute to 2-hour fire rating) to protect cylinders from external fire and delay their involvement.

5. Ventilation: Directs hazardous gases safely to the atmosphere via an exhaust system, preventing the buildup of toxic, flammable, or asphyxiating gases.

6. Security: Lockable doors prevent unauthorized access to hazardous materials.

Common Types & Classifications

Cabinets are categorized by the type of gas they are designed to store:

1. Flammable Gas Cabinets:

· Color: Typically Yellow (common standard, though not universal).

· Features: Double-walled construction, 18-gauge steel, 1.5" air gap for insulation. Includes flame arrestors in vent ports and baffled vents. Must be grounded for static electricity.

· Examples: For acetylene, hydrogen, methane, propane.

2. Corrosive Gas Cabinets:

· Color: Typically Blue or Grey.

· Features: Constructed from corrosion-resistant materials (e.g., polypropylene, PVC-coated steel, stainless steel). Often include built-in secondary containment trays or sumps to capture leaks. Exhaust is mandatory and critical.

· Examples: For chlorine, ammonia, hydrogen chloride, sulfur dioxide.

3. Toxic Gas Cabinets:

· Color: Varies (often grey or custom).

· Features: Highest level of containment and monitoring. Usually include continuous gas monitoring sensors (interlocked with alarms and ventilation), redundant ventilation systems, and automatic cylinder valve shut-offs. May have pass-through boxes for regulator maintenance.

· Examples: For arsine, phosphine, chlorine, carbon monoxide.

4. Oxidizer Gas Cabinets:

· Color: Typically Green.

· Features: Designed to separate oxidizers from flammable materials. Constructed similarly to flammable cabinets but clearly labeled for oxidizers.

· Examples: For oxygen, nitrous oxide, chlorine.

5. General Purpose / Cylinder Storage Cabinets:

· For non-hazardous or inert gases (e.g., nitrogen, argon, helium). Focus is on stability and organization rather than containment or fire rating. May not require forced ventilation.

Gas cylinder cabinet from Jinhua Rio Tinto Steel Cabinet Co., Ltd. Key Design Features & Components as below:

· Construction Material: Heavy duty steel

· Doors: Self-closing, close-fitting doors with locks. Some have viewing windows.

· Leak Containment: Sill or spill containment sump to hold a volume of liquid from a leaking cylinder.

· Cylinder Restraints: Internal chains, straps, or bars to securely anchor cylinders upright.

· Shelving: Adjustable, perforated shelves for smaller cylinders or related equipment.

· Labeling: Prominent hazard warning signs (e.g., "Flammable Gas," "Corrosive," "Oxidizer").

Best Practices for Use

1. Segregation: Never store incompatible gases in the same cabinet (e.g., flammables and oxidizers must be separated).

2. Ventilation: Always connect and use the exhaust system for hazardous gases unless specifically designed as non-ventilated for inert gases. Verify airflow regularly.

3. Grounding: Ground flammable and corrosive gas cabinets to prevent static discharge.

4. Capacity: Do not exceed the maximum number of cylinders recommended by the manufacturer or NFPA limits.

5. Accessibility: Keep aisles and access to cabinets clear. Doors must be able to open fully.

6. Inspection: Regularly inspect cylinders, regulators, cabinets, and restraints for damage.

7. Training: Ensure all personnel are trained on the hazards of the gases and the proper use of the cabinet system.

Q1:Are you a manufacturer?

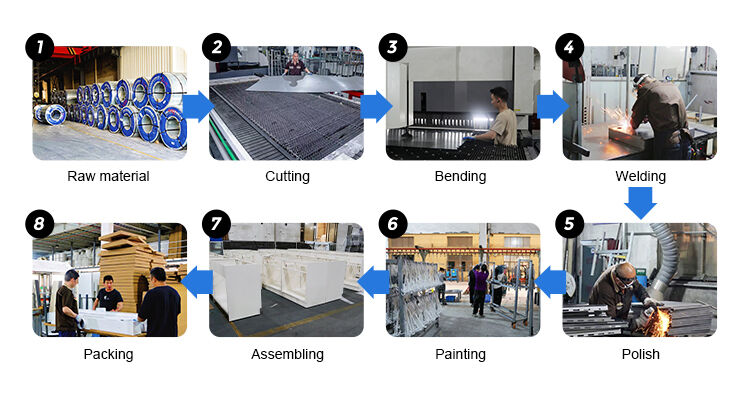

Yes, We are a professional manufacturer with almost 20 years experience of all kinds of lab furniture.

Q2. Where is your factory located?

Our factory is located inJinhuacity, Zhejiang province, China.

Q3. Can you do OEM or ODM?

Yes, our factory offers OEM & ODM services. Professional design: our well-experienced designers will customize according to your specifications.

Q4. How long is the delivery time for bulk order?

Super fast! Our regulardelivery time will be 7-10 working after you confirm all detail information. To large quantities, 15-30 working days.

Q5. How do you ensure product quality?

Customer satisfaction is our priority. We will ensure the stability and excellence of our product by checking from the beginning raw-materials; during production processes and conduct a final quality check before packaging.